What Are Industrial Blades?

Industrial blades are precision-engineered cutting tools fundamental to modern manufacturing and processing. They transform raw materials into finished products with speed and accuracy, used across industries from paper converting and packaging to plastic film processing and metal fabrication. Unlike standard knives, these blades withstand extreme forces, repetitive motion, and challenging materials while maintaining sharpness. Companies like DYYRENT, a Custom Industrial Blades Manufacturer in China, leverage 15+ years of expertise to engineer blades meeting rigorous ISO standards for consistent results.

Key Functions of Industrial Blades

These blades perform critical operations:

- Precision Separation: Cleanly slicing paper, film, foil, textiles, or composites without tearing or fraying.

- High-Speed Processing: Maintaining cutting integrity at production line speeds.

- Shape Creation: Die-cutting cartons, labels, or intricate patterns.

- Material Reduction: Trimming excess from formed products or slitting rolls into narrower widths.

- Surface Finishing: Scraping or planing surfaces to exact specifications.

Different Types of Industrial Blades

The blade type dictates the cut quality and application suitability:

- Shear Cutting Blades: Feature opposing blades meeting at an angle, like scissors. Ideal for clean cuts on paper, film, and thin metals. Examples include Guillotine Knives. Find precision Paper Cutting Blades & Slitting Knives specifically engineered for these tasks at DYYRENT.

- Crush Cutting Blades: Use a sharp blade against a hard anvil roll to fracture brittle materials like carbon fiber or thick plastics.

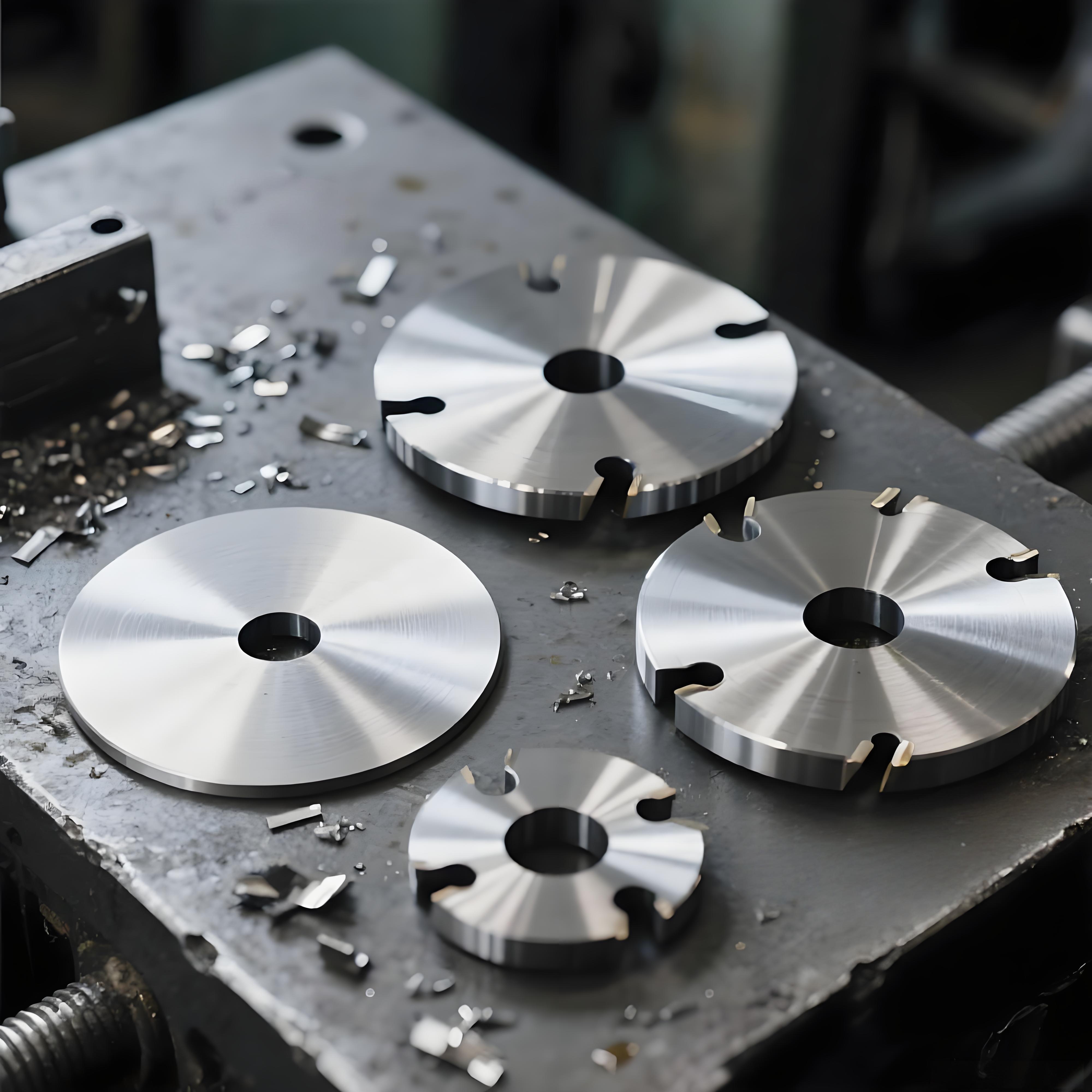

- Slitting Blades (Rotary Slitters): Paired upper and lower circular blades that score or cut continuous webs (e.g., converting large paper rolls into narrow rolls). Tungsten Carbide options excel here.

- Round & Circular Cutters: Used for punching holes, cutting discs, or trimming tubes. Carbide-tipped variants offer superior longevity.

Industrial Blades vs. Standard Cutting Tools: A Comparison

| Feature | Industrial Blades | Standard Cutting Tools |

|---|---|---|

| Purpose | High-volume, precision material processing | General-purpose cutting tasks |

| Durability | Engineered for extended wear under high load | Shorter lifespan under heavy use |

| Material | High-Carbon Steel, Tool Steel, HSS Inlays, Tungsten Carbide | Often mild steel or lower-grade alloys |

| Precision | Tight tolerances (e.g., 0.05mm), sharpness critical | Looser tolerances common |

| Cost | Higher initial investment, lower cost-per-cut | Lower initial cost, higher cost-per-cut |

| Application | Paper converting, packaging lines, textile mills, metal slitting | Workshops, kitchens, light craft work |

| Customization | Routinely customized (dimensions, angles, coatings) | Limited customization options |

High Speed Steel Rotary Slitter Knives

Optimal Materials for Industrial Blade Fabrication

The best material depends entirely on the application:

- High-Carbon Steel (HCS): Cost-effective for moderate use on softer materials like paperboard and textiles. Needs frequent sharpening.

- Tool Steel (e.g., D2, A2): Enhanced wear resistance for longer runs on materials like corrugated board and some plastics.

- High-Speed Steel (HSS) Inlays: Hard welded edges on a softer steel body. Balances cost and cutting performance for demanding applications.

- Tungsten Carbide: The premium choice for extreme wear resistance. Essential for high-speed operations, abrasive materials (glass fiber, carbon fiber), and achieving the longest possible lifespan. Offers the lowest cost-per-cut over time.

When Should You Replace Your Industrial Blades?

Replace your blades when you observe:

- Increased Burring or Rough Edges: Indicates dullness, forcing material tearing instead of clean cutting.

- Reduced Cutting Quality: Noticeable decline in finish or dimensional accuracy.

- Higher Cutting Force Required: Machine strain increases, risking damage or downtime.

- Visible Chipping or Nicks: Physical damage on the cutting edge.

- Excessive Sparks or Heat: Particularly when cutting metals.

- Frequent Snags or Misalignment: Material jams become common.

Key Factors Influencing Industrial Blade Pricing

- Raw Material Cost: Tungsten carbide commands a premium over HCS.

- Manufacturing Complexity: Custom geometry, precision grinding, specialized treatments (cryogenic, coatings), and quality control significantly impact cost.

- Life Expectancy: Blades designed for millions of cuts (like carbide) cost more upfront but deliver lower cost-per-cut.

- Customization: Non-standard sizes, angles, or specific alloy blends increase manufacturing time and cost.

- Technological Features: Coated blades (TiN, CrN), complex inlays, and sensor integration affect price.

- Market Competition: DYYRENT leverages scale and efficient manufacturing to offer competitive pricing without compromising on ISO-certified precision.

Crucial Variables Determining Blade Performance

- Blade Hardness & Toughness: Hardness resists wear; toughness prevents chipping (needs balance).

- Edge Geometry: The angle and finish determine cutting force and finish quality (e.g., acute angles for fine materials).

- Material Composition: Homogeneity ensures consistent performance across the blade length.

- Runout & Alignment: Critical for paired blades (slitters) to avoid poor cuts and premature wear.

- Proper Mounting & Tension: Ensures stable cutting and minimizes vibration/chatter.

Common Causes of Industrial Blade Failure & Prevention

- Dull Edges (Most Common): Prevention: Implement regular resharpening schedules & optimize feed/speed rates.

- Improper Installation: Prevention: Follow manufacturer torque specs and alignment procedures strictly.

- Material Incompatibility: Prevention: Select the right blade material and geometry for the job (consult DYYRENT's 24/7 technical support).

- Overheating: Prevention: Use coolants/lubricants where applicable; monitor blade & material temps.

- Edge Chipping: Prevention: Avoid cutting hard contaminants; ensure blade toughness matches material.

- Corrosion: Prevention: Choose corrosion-resistant alloys/stainless; use proper storage.

Essential Maintenance Tips for Industrial Blades

- Professional Resharpening: Use services specializing in precise industrial blade regrinding to maintain original geometry. DYYRENT offers expert resharpening.

- Proper Cleaning: Remove adhesive build-up and debris after use.

- Correct Storage: Store blades vertically in dedicated holders or racks, protected from environmental moisture and impacts. Consider protective coatings for storage.

- Regular Inspections: Check for wear, micro-chipping, nicks, or corrosion.

- Follow Manufacturer Specs: Adhere to mounting, tensioning, and operational guidelines. Never mix unmatched blade pairs.

Key Components of High-Performance Industrial Blades

- Cutting Edge: The point of contact; defined by material, sharpness, and angle. Precision ground.

- Body: Provides structural support; material chosen for stability and compatibility.

- Mounting Hole/Shank: Ensures perfect centering and secure mounting to the arbor/spindle. Precision-machined.

- Bevel/Face Geometry: Angles behind the edge that guide material flow and support the edge.

- Coatings (Optional): Applied layers (e.g., TiN, CrN) to reduce friction, enhance wear resistance, and prevent corrosion.

Innovations in Industrial Blade Design & Manufacturing

- Advanced Coatings: Multi-layered nanocomposite coatings dramatically reduce friction and extend life.

- Precision Edge Conditioning: Electron microscopy ensures atomic-level edge perfection.

- Smart Blade Technology: Sensors embedded to monitor blade wear, temperature, and performance in real-time (emerging tech).

- Material Science: Development of next-gen carbide grades and engineered ceramics for niche applications.

- Additive Manufacturing: 3D printing for highly complex near-net-shape blade bodies, reducing machining time and waste.

Do All Industrial Cutting Machines Use Specific Blades?

Absolutely. The blade type and specification are intrinsically linked to the machine (guillotine cutter, rotary press, winder/slitter, laser-supported cutter, etc.) and the exact material being processed. Using the wrong blade can be catastrophic. Always consult machine manuals and reputable blade suppliers like DYYRENT for the precise blade recommended for your equipment and application.

What Defines a Good Industrial Blade in Packaging?

A top-tier packaging blade combines:

- Razor-Sharp Edge: For clean cuts without tearing corrugated fluting or delaminating laminated board.

- Exceptional Wear Resistance: To maintain sharpness throughout long production runs on abrasive materials.

- Precise Geometry: Especially critical for complex die shapes or kiss cuts.

- Material Integrity: Resists chipping on staples, adhesives, or contaminants found in recycled board.

- Customization: Ability to match the exact dimensions and requirements of the cutting die or slitting assembly.

DYYRENT's expertise in custom blades for paper processing and packaging ensures these critical factors are met.

Conclusion: Precision Cutting Starts with the Right Blade

Industrial blades are the unsung heroes of manufacturing efficiency and product quality. Selecting the optimal blade—considering material, geometry, application, and machine—is paramount. Understanding the factors affecting performance, lifespan, and cost empowers informed purchasing decisions.

For manufacturers prioritizing reliability, precision, and value, partnering with a proven expert is key. DYYRENT is your Trusted manufacturer of precision industrial blades. With ISO-certified processes, 15+ years of experience in crafting custom solutions for paper, packaging, film, and industrial cutting, global delivery, and unparalleled 24/7 technical support, we ensure your cutting operations run at peak efficiency. Explore our comprehensive range of Industrial Precision Tools, including specialized Paper Cutting Blades & Slitting Knives. Request free samples or inquire about bulk discounts today.

More Resources:

- Industrial Knife Overview

- Fundamentals of Metal Cutting

- Selecting Cutting Tool Materials

- Understanding Blade Coatings