The Diverse Application Potential of Circular Blades: Innovations in Cutting Technology and the Redefinition of Experience

——DYYRENT unlocks the infinite possibilities of circular blades with cutting-edge technology

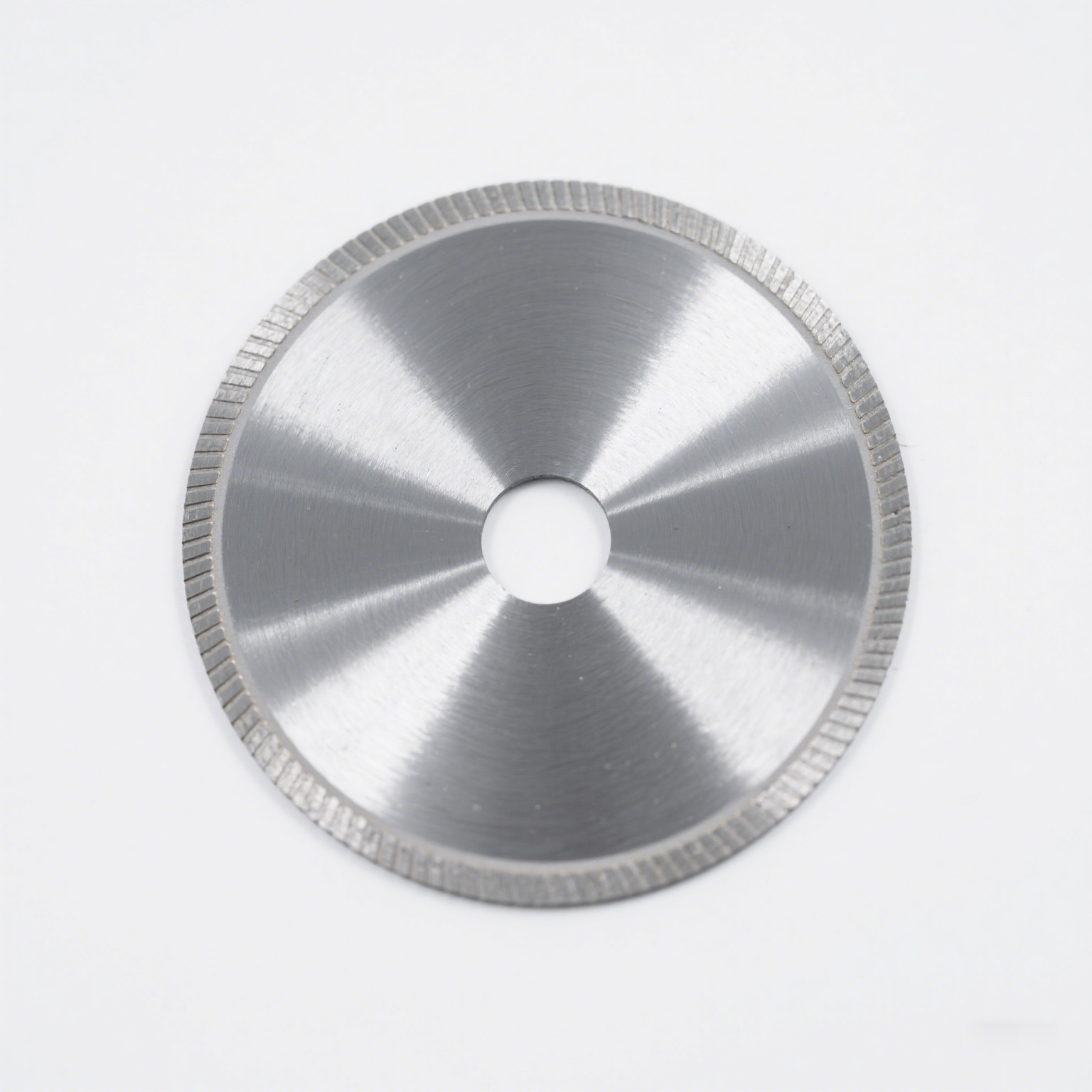

In modern industry and daily life, Dyyrent's circular blades, with their exceptional quality, durability, and comprehensive range of models, are quietly revolutionizing cutting technology and reshaping the public's perception of cutting processes. From metalworking factories to art studios, from production lines to cozy kitchens, Dyyrent's circular blades, with their glistening edges, demonstrate unparalleled precision and efficiency across various scenarios.

Entering the bustling metalworking factory, the large circular blades on Dyyrent's CNC slitting machines resemble the sharp teeth of mechanical giants, exuding a cold metallic luster. These meticulously polished blades can reach a diameter of over one meter. Once the equipment is activated, they spin at a staggering speed of 2,000 revolutions per minute. When the alloy steel coils are fed in, the blades penetrate instantly, creating tiny sparks as the edges make contact with the metal, and the sound of cutting forms a stirring mechanical symphony. Thanks to Dyyrent's innovative concentric stress design, even when faced with high-strength steel plates 5 millimeters thick, the cutting accuracy error of the blades is only 0.02 millimeters. This ensures that each strip of metal cut can become high-quality components required by high-end manufacturing industries such as automotive and aerospace, helping metal raw materials transform into precision parts.

In the metal processing industry, Dyyrent's 300-millimeter-diameter alloy circular saw blades also deliver outstanding performance. The edges of these blades are treated with a special coating, providing both high wear resistance and long-lasting sharpness. When metal sheets are placed on the sawing machine, the circular saw blades reach a linear speed of 80 meters per second. Their unique wave-shaped edge design effectively distributes cutting forces, reducing vibrations and ensuring a smooth and stable cutting process. Whether it's the processing of precision instrument parts or the construction of large mechanical metal frames, Dyyrent's circular blades can accurately transform engineers' design blueprints into physical objects, enhancing the efficiency and quality of industrial manufacturing. In the realm of daily life, Dyyrent's circular blades are omnipresent, bringing convenience and pleasant experiences to people.

In popular baking studios, Dyyrent's titanium-plated circular pizza cutters glide effortlessly across freshly baked Italian thin-crust pizzas. The ultra-thin 0.3-millimeter blade precisely severs the cheesy strands while perfectly preserving the crispness of the crust, making every bite brimming with happiness. The round-tipped scissors used by tailors, with their curved blades made from aviation-grade titanium alloy, generate only one-third of the friction of ordinary scissors when cutting delicate fabrics like silk. With a gentle turn, they can create graceful curves, such as those of a cheongsam collar, adding an exquisite touch to traditional clothing. In printmaking studios, Dyyrent's miniature circular carving knives, with a diameter of less than 2 millimeters, are like nimble paintbrushes in the hands of artists, carving delicate patterns on basswood and bringing stunning printmaking works to life, showcasing unique artistic charm.

The reason why Dyyrent's circular blades shine in various fields is inseparable from continuous technological innovation. The nanoscale coating technology provides the blades with an invisible "armor," reducing frictional heat by 60% and extending the blade life to five times that of ordinary products. The vacuum ion implantation process enables the blades to achieve a hardness exceeding HRC70. Even after 1,000 hours of continuous cutting, the edge wear is less than 0.01 millimeters. Before leaving the factory, each Dyyrent circular blade undergoes rigorous inspection by a coordinate measuring machine to ensure that every arc surface and every tooth meets strict industrial standards, entering the market in optimal condition.

Dyyrent's circular blades have extensive applications and an extremely comprehensive range of models. From 50-millimeter-diameter miniature carving knives to 2,000-millimeter industrial slitting knives, over 100 standard models are always in stock, and custom services for various sizes are also available. No matter what your cutting needs are, Dyyrent's professional team can customize the best solution for you and provide an instant quote within 2 hours, helping you embark on a new experience of efficient and precise cutting! Contact us now!

——DYYRENT unlocks the infinite possibilities of circular blades with cutting-edge technology

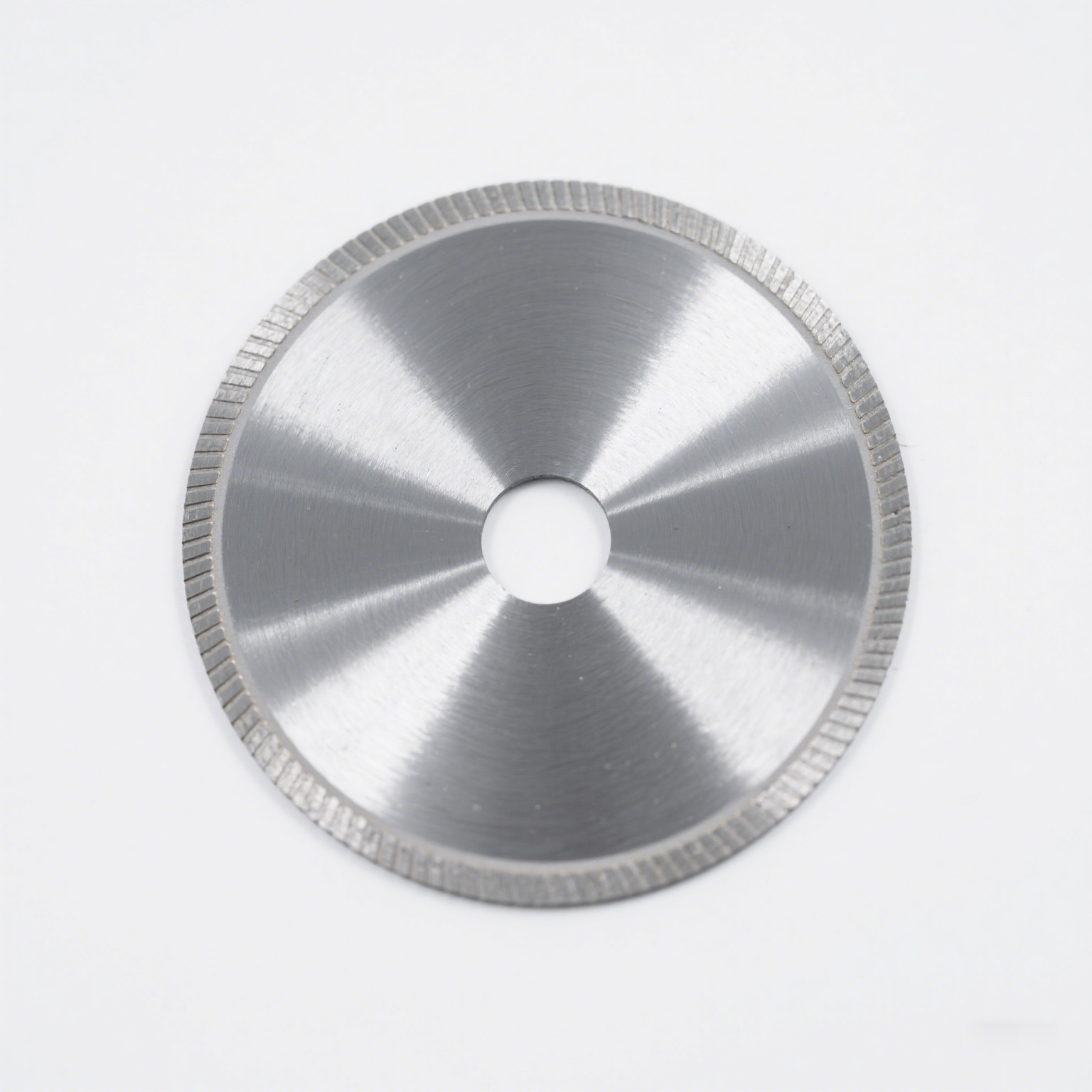

In modern industry and daily life, Dyyrent's circular blades, with their exceptional quality, durability, and comprehensive range of models, are quietly revolutionizing cutting technology and reshaping the public's perception of cutting processes. From metalworking factories to art studios, from production lines to cozy kitchens, Dyyrent's circular blades, with their glistening edges, demonstrate unparalleled precision and efficiency across various scenarios.

Entering the bustling metalworking factory, the large circular blades on Dyyrent's CNC slitting machines resemble the sharp teeth of mechanical giants, exuding a cold metallic luster. These meticulously polished blades can reach a diameter of over one meter. Once the equipment is activated, they spin at a staggering speed of 2,000 revolutions per minute. When the alloy steel coils are fed in, the blades penetrate instantly, creating tiny sparks as the edges make contact with the metal, and the sound of cutting forms a stirring mechanical symphony. Thanks to Dyyrent's innovative concentric stress design, even when faced with high-strength steel plates 5 millimeters thick, the cutting accuracy error of the blades is only 0.02 millimeters. This ensures that each strip of metal cut can become high-quality components required by high-end manufacturing industries such as automotive and aerospace, helping metal raw materials transform into precision parts.

In the metal processing industry, Dyyrent's 300-millimeter-diameter alloy circular saw blades also deliver outstanding performance. The edges of these blades are treated with a special coating, providing both high wear resistance and long-lasting sharpness. When metal sheets are placed on the sawing machine, the circular saw blades reach a linear speed of 80 meters per second. Their unique wave-shaped edge design effectively distributes cutting forces, reducing vibrations and ensuring a smooth and stable cutting process. Whether it's the processing of precision instrument parts or the construction of large mechanical metal frames, Dyyrent's circular blades can accurately transform engineers' design blueprints into physical objects, enhancing the efficiency and quality of industrial manufacturing. In the realm of daily life, Dyyrent's circular blades are omnipresent, bringing convenience and pleasant experiences to people.

In popular baking studios, Dyyrent's titanium-plated circular pizza cutters glide effortlessly across freshly baked Italian thin-crust pizzas. The ultra-thin 0.3-millimeter blade precisely severs the cheesy strands while perfectly preserving the crispness of the crust, making every bite brimming with happiness. The round-tipped scissors used by tailors, with their curved blades made from aviation-grade titanium alloy, generate only one-third of the friction of ordinary scissors when cutting delicate fabrics like silk. With a gentle turn, they can create graceful curves, such as those of a cheongsam collar, adding an exquisite touch to traditional clothing. In printmaking studios, Dyyrent's miniature circular carving knives, with a diameter of less than 2 millimeters, are like nimble paintbrushes in the hands of artists, carving delicate patterns on basswood and bringing stunning printmaking works to life, showcasing unique artistic charm.

The reason why Dyyrent's circular blades shine in various fields is inseparable from continuous technological innovation. The nanoscale coating technology provides the blades with an invisible "armor," reducing frictional heat by 60% and extending the blade life to five times that of ordinary products. The vacuum ion implantation process enables the blades to achieve a hardness exceeding HRC70. Even after 1,000 hours of continuous cutting, the edge wear is less than 0.01 millimeters. Before leaving the factory, each Dyyrent circular blade undergoes rigorous inspection by a coordinate measuring machine to ensure that every arc surface and every tooth meets strict industrial standards, entering the market in optimal condition.

Dyyrent's circular blades have extensive applications and an extremely comprehensive range of models. From 50-millimeter-diameter miniature carving knives to 2,000-millimeter industrial slitting knives, over 100 standard models are always in stock, and custom services for various sizes are also available. No matter what your cutting needs are, Dyyrent's professional team can customize the best solution for you and provide an instant quote within 2 hours, helping you embark on a new experience of efficient and precise cutting! Contact us now!