Nordic Paper Solutions

"DYYRENT's tungsten carbide guillotine blades extended our cutting life by 300% compared to previous suppliers. We now process 8,000 tons of kraft paper between sharpenings while maintaining ±0.005mm edge consistency."

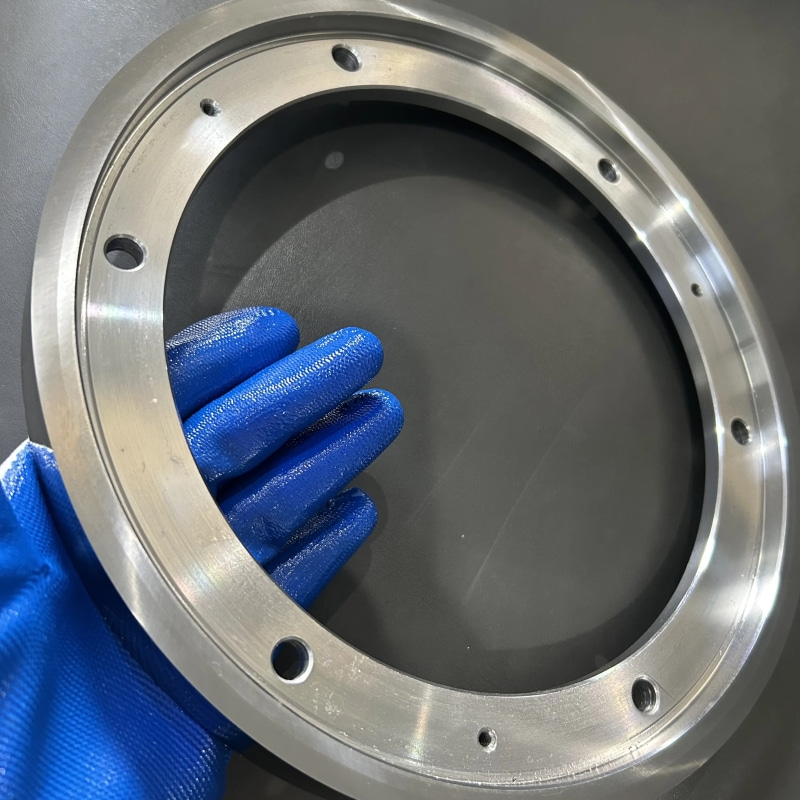

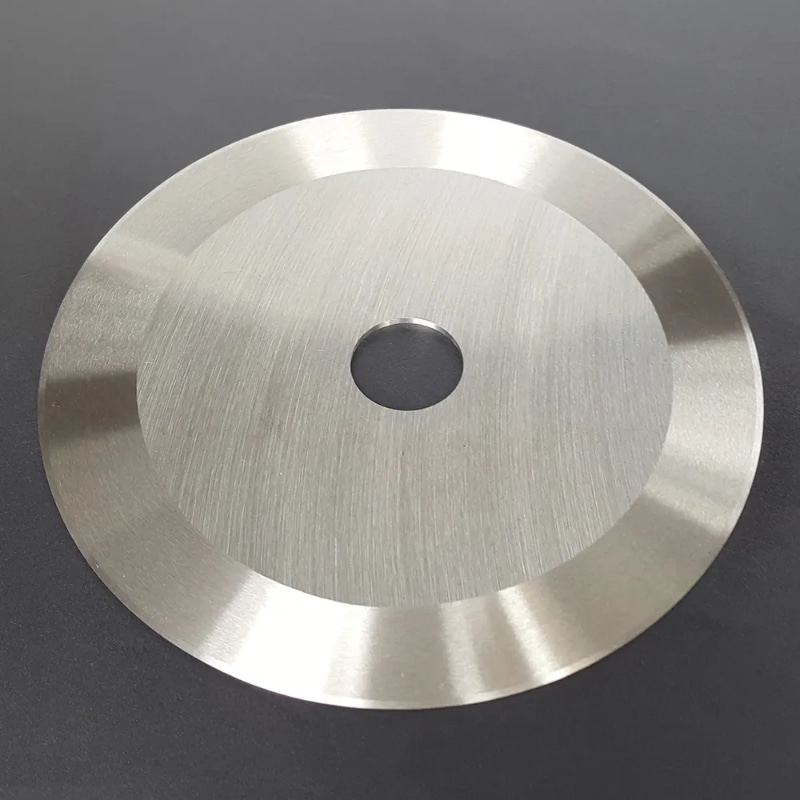

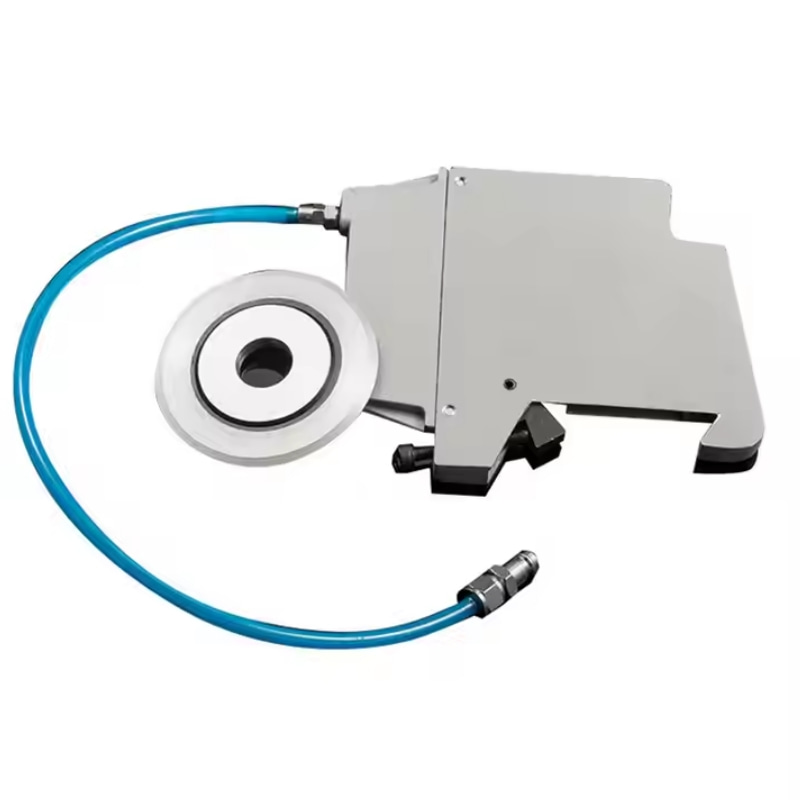

DYYRENT manufactures and supplies CUSTOM and OEM paper cutting blades and trimmers. All our paper cutting blades are engineered to exceed customers' requirements and meet stringent OEM specifications.Our blades are produced in various configurations including circular, straight, curved, toothed, and scalloped designs, specialized for paper cutting processes such as slitting, rewinding, sheeting, perforating, guillotine cutting, and precision trimming. We manufacture custom paper cutting blades per technical drawings or samples, delivering superior products that surpass specifications at competitive prices with industry-leading lead times (as fast as 2 weeks).

Precision Cutting Solutions

With 15+ years of specialization, DYYRENT engineers high-precision blades for paper cutting applications. Our German-grade tungsten carbide and high-speed steel blades deliver clean cuts with extended edge life. Certified to ISO & CE standards with 3-year performance guarantee.

We develop custom blades for all paper processing needs - from guillotine knives for bulk cutting to circular blades for intricate patterns. Our blades handle newsprint, cardboard, and specialty papers with micron-level accuracy, preventing fiber tear while maximizing production efficiency.

Our R&D pioneers multi-layer coatings and sensor-embedded blades that monitor wear in real-time. Supported by global technicians, we provide 24/7 cutting optimization advice, on-site blade maintenance, and operator training programs for slitting, perforating, and die-cutting operations.

Contact us for a price

Speak To Paper Cutting Blades Specialist

As a direct manufacturer, we offer German-grade carbide blades at factory prices, saving clients up to 80% versus competitors.

Blades engineered to Ra0.2-Ra0.4 surface roughness with ±0.01mm tolerance, ISO 9001 certified and backed by 3-year performance guarantee.

Real-time troubleshooting for slitting, perforating and guillotine operations with on-site sharpening services globally.

In-stock blades ship in 3 days; custom orders with CNC grinding/TiCN coating delivered in 15 days - 60% faster than industry average.

Triple-inspection protocol: material spectrometry, hardness mapping (HRC58-68), and cutting simulation before shipment.

Material science expertise for paper-specific solutions: anti-friction coatings for cardboard, micro-serrated edges for photo paper, tapered geometries for high-speed rewinding.

– Standard blades: Shipped in 3 working days from stock

– Custom blades: 15 days for CNC grinding/TiCN coating (60% faster than industry average)

– Tungsten carbide: German-grade for extended edge life (ideal for cardboard/corrugated paper)

– High-speed steel: HRC58-68 hardness for precision cutting

– Specialty alloys: Micro-serrated edges for photo paper, anti-friction coatings for synthetic materials

– MOQ: 1 piece for custom designs

– Submit samples or technical drawings for blades optimized for:

• Guillotine cutting (thick paper stacks)

• Slitting/rewinding (high-speed operations)

• Perforating/scoring (specialty applications)

– Triple-inspection protocol:

1. Material spectrometry verification

2. Hardness mapping (HRC58-68 tolerance)

3. Cutting simulation tests

– 3-year performance guarantee against edge chipping

– Apply paraffin wax during cutting to reduce friction

– Use oilstone for edge refinement before installation

– Store in temperature-controlled dry environment to prevent corrosion

– 24/7 cutting optimization: Real-time troubleshooting for fiber tear issues

– On-site sharpening services with CNC regrinding equipment

– Blade performance analysis using digital wear sensors

– Sample blades available for production validation

– Customer covers shipping; sample cost credited to bulk orders

– Test reports provided with cutting force measurements

– ISO 9001:2008 certified manufacturing

– CE compliance for EU market access

– Material traceability documentation

Trusted by manufacturers in 120 countries worldwide

"DYYRENT's tungsten carbide guillotine blades extended our cutting life by 300% compared to previous suppliers. We now process 8,000 tons of kraft paper between sharpenings while maintaining ±0.005mm edge consistency."

"The micro-serrated blades for corrugated board eliminated fiber tear on our 350m/min production lines. Maintenance downtime reduced from 8 hours/week to just 2 hours, increasing annual output by 18,000 tons."

"For carbon fiber reinforced polymers (CFRP), DYYRENT's diamond-coated blades achieved 12,000 clean cuts without delamination. This reduced our material waste by 22% and passed Airbus AS9100 quality audits."

"Precision scalloped blades for synthetic filter media increased cutting accuracy to ±0.01mm. Rejection rate dropped from 4.5% to 0.2%, saving €480,000 annually in material costs for our BMW/Mercedes supply contracts."

"Toothed blades for mixed waste processing lasted 6x longer than competitors' products. We now process 120 tons/hour of packaging waste with only 2 blade changes per shift, reducing operational costs by €11/ton."

"For banknote substrate cutting, DYYRENT's anti-static blades achieved zero particulate contamination. This met ISO 14298 security standards while increasing production speed by 40% versus previous solutions."

You will get a guaranteed response within 24 hours.